CEEM's Lianyang Zhang and MSE's Krishna Muralidharan Collaborate on DOE Geopolymer Proposal

Faculty and students of the Departments of Civil Engineering and Engineering Mechanics (CEEM) and Materials Science and Engineering (MSE) are collaborating on a Department of Energy (DOE) proposal to develop a fundamental characterization of the structure and properties of geopolymers used for strength enhancement of concrete. The proposal is a collaboration between Dr. Lianyang Zhang, Associate Professor in Geomechanics and Geotechnical Engineering with the Department of Civil Engineering and Engineering Mechanics and Dr. Krishna Muralidharan, Assistant Professor in the Department of Materials Science and Engineering with a focus on developing advanced thermal management systems for applications in energy-efficient devices. The DOE proposal, to be submitted this October, is through the National Science Foundation (NSF), and the collaboration also involves Abu Asaduzzaman, a senior postdoc in MSE, and Mohammad Rafat Sadat, a PhD student in CEEM.

In recent years, researchers have specialized in developing construction materials that are environmentally sound, giving specific focus to utilizing industrial waste byproducts to manufacture products with an eye towards sustainable development. Geopolymers are relatively new materials, developed in the 1960s, that are frequently used for fire- and heat-resistant coatings and adhesives.

Geopolymers have outstanding mechanical properties similar to typical "portland" cement, but they emit approximately 80-90% less CO2 during production, which means the consumption of considerably less energy during production than ordinary polymers. Geopolymers can also be developed using manufacturing byproducts that would otherwise remain industrial waste. Dr. Zhang notes that this sustainable use of geopolymers will make a major impact in the mining industry, where mining waste is a large environmental concern.

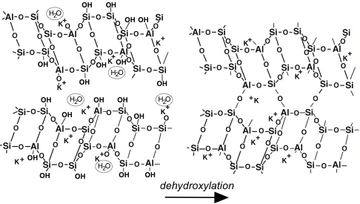

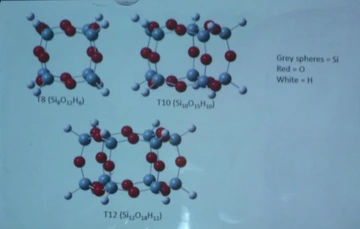

Dr. Zhang notes that MSE Postdoc Asaduzzaman is working on understanding what happens with geopolymers at the basic molecular level, and that Asaduzzaman will build simulations at an atomic scale and then will reproduce the simulations in real scale. "Most of the research we are doing focuses on experimental uses of geopolymers," Dr. Zhang says. "However, people still don't understand the building blocks of this material. What is the exact molecular structure of a geopolymer? How do you produce a better geopolymer? These questions are why we want to use techniques to study the molecular structure of this new type of material. Geopolymer materials were first discovered in the 1960's, but they were not used frequently for production purposes until the 1970's through the 1980's. The reason for its growth in popularity is this is a new type of material which is more sustainable than ordinary polymer cement."

Dr. Zhang has been studying geopolymers for the past five years. He says that so far, most research has focused on the experimental use of geopolymers. "Now people are trying to think about how to design materials and in order to do that, you must understand the material's molecular structure," he says. "Water plays an important part in how stable and robust the material is and water helps determine that. Does water break the bonds? Additives play an important part in determining the characteristics of a material. What should be the constituents and proportions of additives that enhance and hurt the material?"

Dr. Zhang also points out that this research focus falls within the framework of the Materials Genome Initiative, referring to a recent initiative by the White House to encourage the manufacture of materials at a faster rate and at a fraction of the cost of traditional materials.

Dr. Zhang notes that the collaboration came about because he wanted CEEM PhD student Sadat to do molecule dynamics modeling, but as Sadat did not have this background, Dr. Zhang suggested an Integrated Computational Materials Science and Engineering (ICSME) course. With this consideration, Dr. Zhang then realized that the materials expertise in the MSE Department would greatly contribute to his research, and this led to the collaboration between CEEM and MSE.