Wessman Developing Sensors to Improve 3D Printing Process

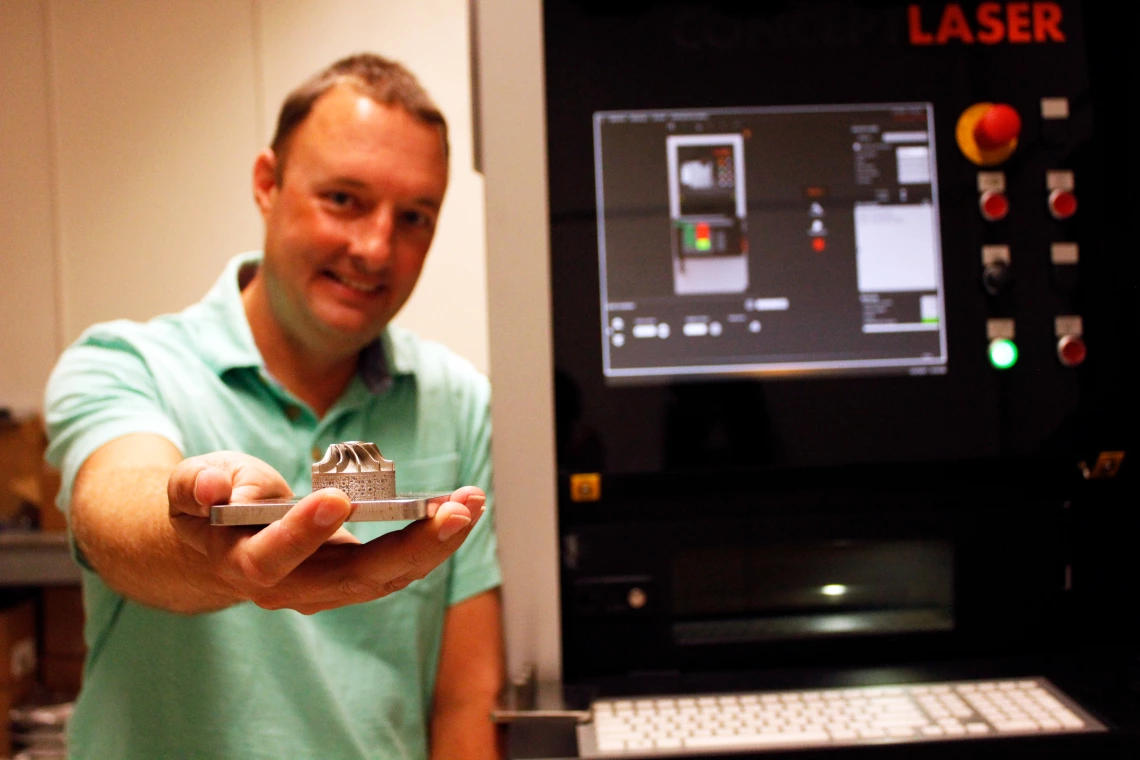

MSE assistant professor Andrew Wessman is working to ensure 3D-printed parts achieve a higher standard of quality. In an article from the American Society of Mechanical Engineers, Wessman explains how he and systems and industrial engineering assistant professor Mohammed Shafae are developing a suite of sensors to monitor the printing process and detect when and where problems may occur.

“These are very complex geometries that are difficult to inspect,” Wessman said. “We’re going to come up with a way to detect anomalies that occur during the process so we can start to analyze and classify them into different categories based on the information we get from the sensors.”

3D printing anomalies can occur from "random variation" with the materials such as vaporization or cracking. The sensor suite, which includes thermal imaging and high-speed cameras, can better the process for printing jet engine parts.

“You’re never going to make a perfect part,” Wessman explained. “But in the aviation industry, we must understand the levels of imperfection that we can tolerate within the material.”